How Picoliter Dispensing is Transforming Scientific Research and Innovation

How Picoliter Dispensing is Transforming Scientific Research and Innovation

In modern research, precision is everything. As scientists push the boundaries of innovation, picoliter dispensing has become an important tool, enabling ultra-miniaturized assays, reducing reagent waste, and enhancing experimental accuracy. Whether in biotech, diagnostics, or materials science, this technology brings speed without compromising quality and savings without reducing research output. From high-density biochips to biosensors, Microdispensing is enhancing workflows and empowering researchers to make groundbreaking discoveries. This article explores three key precision microdispensing applications, emphasizing the crucial role of automated picoliter-scale dispensing in advancing the next generation of scientific breakthroughs.

Why Picoliter Precision Matters in Modern Research

Modern research and development continually harnesses technological advancements to optimize resource allocation and streamline research objectives. One of the most notable examples of this progress is assay miniaturization, which allows researchers to obtain faster, more reliable results while reducing reagent consumption and minimizing hands-on time [1], [2]. Progress in this field has partly been driven by the development of picoliter precision dispensing technologies.

Accurate dispensing of increasingly low volumes empowers progress across biotech, diagnostics, and materials science applications. Picoliter dispensing simplifies and enhances highly sensitive molecular techniques in several key ways, including:

- Accuracy – Modern picoliter dispensers achieve accurate repeated dispensing of volumes as low as 10 pL. The droplet size is minuscule, roughly equivalent to three red blood cells arranged end-to-end.

- Density – The ability to dispense tiny droplets enables high-density sample arrays, maximizing data output while conserving reagents.

- Non-contact – Non-contact dispensing eliminates the risk of cross-contamination and ensures precise delivery.

- Automation – Automated processes enhance workflow efficiency by enabling high-throughput processing and reducing the potential for human error [3].

- Miniaturization – Precise dispensing minimizes reagent waste and maximizes the usability of rare or expensive samples.

Breakthrough Application #1: Biosensors

Many diagnostic workflows depend on the precise and sensitive detection of molecules within complex biological samples such as human-derived and environmental specimens. Biosensors are increasingly important in this space, providing rapid, reliable, and cost-effective solutions for detecting biomarkers and pathogens in real time, making them essential tools in modern diagnostics and beyond [4]. Environmental biosensors play a critical role in monitoring pollutants, detecting hazardous substances, and assessing ecosystem health, expanding the impact of biosensors beyond clinical applications [5].

Biosensors in Action

In a recent publication, researchers utilized CRISPR technology to detect pathogens in patient samples through Cas12a/gRNA-mediated cleavage of DNA probes labeled with methylene blue. Such a system can theoretically detect any nucleic acid sequence, offering exciting possibilities for robust and flexible diagnostic tests [6].

Microdispensing plays a crucial role in the fabrication of biosensors, ensuring precise reagent placement. By enabling accurate molecular detection while using minimal amounts of patient or environmental samples, picoliter dispensers enhance biosensor performance and reliability. Here’s why picoliter dispensing is an essential tool for advancing biosensor technology:

- Improved detection – Picoliter dispensing enables the precise placement of biomolecules in ultra-small volumes, increasing biosensor sensitivity to detect even trace amounts of target analytes in minimally diluted biological or environmental samples [7].

- Assay robustness – Ensures consistent and reproducible deposition of reagents, reducing variability between biosensors and improving assay reliability, which is crucial for clinical diagnostics and environmental monitoring [8].

- Automated production – Enables high-throughput and scalable biosensor manufacturing, minimizing human error and increasing efficiency, making it easier to produce reliable diagnostic tools for widespread use.

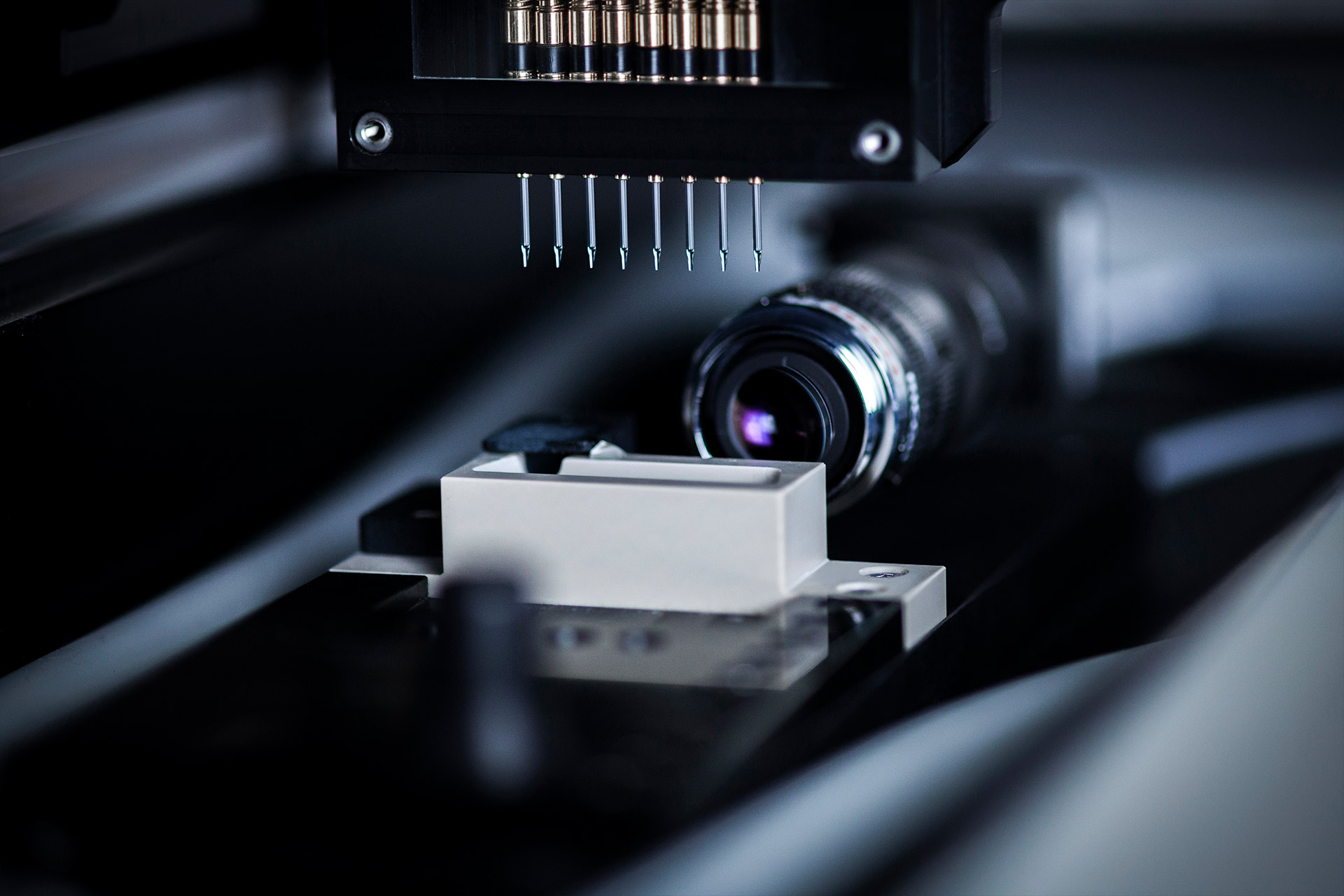

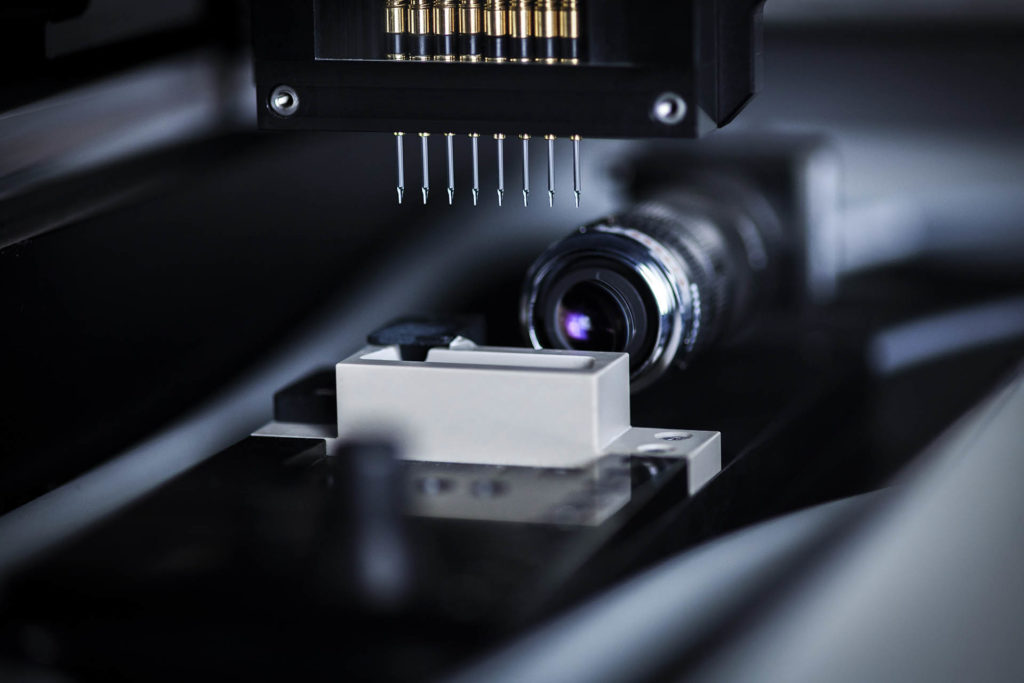

The highly versatile SCIENION’s sciDROP PICO microdispensing technology is compatible with a wide range of liquid types and is able to dispense any liquid volume from 10 pL to 100 µL, making it ideal for handling diverse sample types across broad biomedical applications.

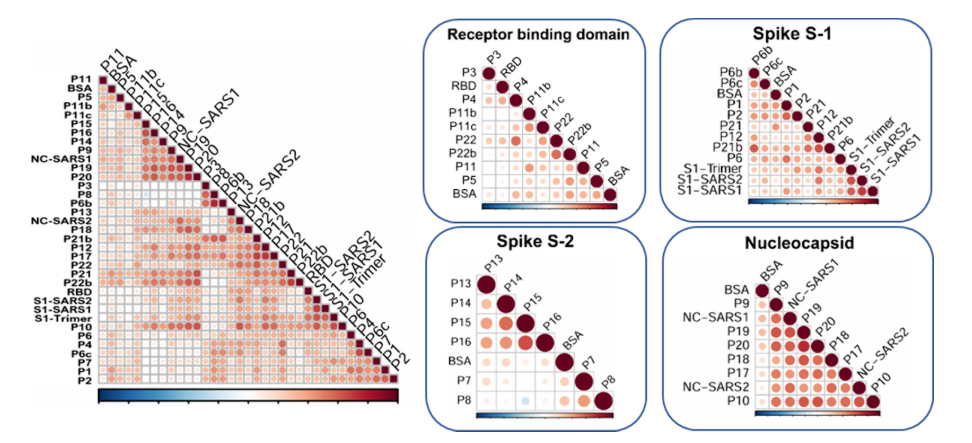

Breakthrough Application #2: Microarrays and High-Density Biochips

Microarrays and high-density biochips are laboratory tools that generate large volumes of genetic, proteomic, or biochemical information by detecting molecular interactions on a miniaturized, high-throughput platform. Microarrays are produced by dispensing arrays of dozens to thousands spots of reagents in nano- or pico-volumes, in precise patterns. Microarrays are widely understood to be used for genomic and transcriptomic analyses but can also be applied to proteome exploration. For example, using the sciFLEXARRAYER S3 from SCIENION, researchers created a multiplex array to evaluate individual responses to SARS-CoV-2 infection. This high-throughput, miniaturized platform enabled the detection of molecular interactions by analyzing patient sera binding to 28 different peptide epitopes and seven proteins on a 25 mm2 area of a glass slide (Fig. 1) [9].

Figure 1. Researchers used the sciFLEXARRAYER S3 to create a protein array to test for patient response to SARS-CoV-2 infections. Adapted from: https://pubs.acs.org/doi/full/10.1021/acsptsci.4c00727

These tools rely on highly sensitive liquid handling techniques, and their accuracy can be compromised if liquid dispensing is not precise and consistent during the fabrication of the array [10],[11]. Picoliter dispensing facilitates the miniaturization and automation of molecular array production workflows, resulting in faster and more reliable fabrication and improved accuracy over manual methods.

By adding multiple spots, each dedicated to the detection of a distinct biomolecule (such as the epitopes in Figure 1), picoliter dispensing enables the simultaneous analysis of multiple biomarkers, proteins, or genes within a single experiment, increasing throughput and efficiency while minimizing reagent use, as well as the volume of sample to be analysed.

Breakthrough Application #3: Drug Screening

Drug screening applications in biological and chemical research are challenging due to errors in manual dispensing and high reagent costs [12], [13]. Large-scale screening can be prohibitively expensive, while cell-based assays add variability and timing constraints, as cells respond differently depending on exposure duration.

Microdispensing addresses these challenges by enabling highly accurate, repeatable experiments at a tiny scale. Their precision minimizes waste, reduces costs, and ensures reliable results, making them invaluable for efficient and scalable screening applications.

- Reproducibility – Automated picoliter dispensing ensures consistent, error-free liquid handling, enhancing data reproducibility in drug screening [12].

- Cost-savings – Ultra-small volumes reduce reagent costs and waste, enabling more cost-effective large-scale drug screening.

- Versatility – Picoliter dispensing can be applied to various research areas, including chemical reaction monitoring, drug dose-response studies, biomarker discovery, and microarray printing (Fig. 2).

- Efficiency – Automated high-throughput dispensing accelerates screening, enabling rapid drug discovery and large-scale assays [1].

SCIENION sciDROP PICO precision dispenser technology enables precise dispensing of live cells with acoustic technology, preventing shear stress and providing reliability for cell-based screening, all while achieving zero dead volume.

Figure 2. sciDROP PICO technology achieves accurate dispensing from the nanoliter scale down to 10 pL of liquids of varying viscosities, including organic solvents. This gives researchers the flexibility to tackle complex workflows at any scale. sciFLEXARRAYER microdispensers may be equipped with up to 8 dispensing capillaries, dramatically increasing picoliter dispensing throughput.

How Picoliter Dispensing is Shaping the Future of Research

Microdispensing technology revolutionizes research by offering precision, minimizing reagent waste, and improving reproducibility. Across several precision microdispensing applications, from microarrays to biosensors and drug screening, these advancements enable more efficient workflows without compromising data quality. Nanoliter pipetting is also important in this area and supports broad applications in combination with picoliter dispensing. As automation and precision liquid dispensing become increasingly essential in modern research, adopting cutting-edge microdispensing solutions like SCIENION’s technology will ensure superior results and future-proof workflows.

Explore SCIENION’s microdispensing solutions today and unlock the full potential of miniaturized, high-precision experiments.

References

- Silva TC, Eppink M, Ottens M. Automation and miniaturization: enabling tools for fast, high‐throughput process development in integrated continuous biomanufacturing. J of Chemical Tech & Biotech. 2022;97(9):2365-2375. doi:10.1002/jctb.6792

- Cole RH, Tang SY, Siltanen CA, et al. Printed droplet microfluidics for on demand dispensing of picoliter droplets and cells. Proc Natl Acad Sci USA. 2017;114(33):8728-8733. doi:10.1073/pnas.1704020114

- Holland I, Davies JA. Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol. 2020;8(571777). doi:10.3389/fbioe.2020.571777

- Liu Z, Zhou Y, Lu J, et al. Microfluidic biosensors for biomarker detection in body fluids: a key approach for early cancer diagnosis. Biomark Res. 2024;12(1):153. doi:10.1186/s40364-024-00697-4

- Li Y, Chen B, Yang S, et al. Advances in environmental pollutant detection techniques: Enhancing public health monitoring and risk assessment. Environment International. 2025;197:109365. doi:10.1016/j.envint.2025.109365

- Carota AG, Bonini A, Urban M, et al. Low-cost inkjet-printed nanostructured biosensor based on CRISPR/Cas12a system for pathogen detection. Biosensors and Bioelectronics. 2024;258:116340. doi:10.1016/j.bios.2024.116340

- Siavashy S, Soltani M, Rahimi S, Hosseinali M, Guilandokht Z, Raahemifar K. Recent advancements in microfluidic-based biosensors for detection of genes and proteins: Applications and techniques. Biosensors and Bioelectronics: X. 2024;19:100489. doi:10.1016/j.biosx.2024.100489

- Beach ER, Benkstein KD, Montgomery CB, Semancik S, Morris PA. Picoliter drop deposition of SnO2 nanoparticles onto microsensor platforms. Sensors and Actuators B: Chemical. 2024;403:135152. doi:10.1016/j.snb.2023.135152

- Guercetti J, Alorda M, Sappia L, et al. Immuno- μSARS2 Chip: A Peptide-Based Microarray to Assess COVID-19 Prognosis Based on Immunological Fingerprints. ACS Pharmacol Transl Sci. 2025;8(3):871-884. doi:10.1021/acsptsci.4c00727

- Wong EY, Diamond SL. Advancing microarray assembly with acoustic dispensing technology. Anal Chem. 2009;81(1):509-514. doi:10.1021/ac801959a

- Shukla V, Hussin F, Hamid N, Zain Ali N. Advances in Testing Techniques for Digital Microfluidic Biochips. Sensors. 2017;17(8):1719. doi:10.3390/s17081719

- Lippi G, Lima-Oliveira G, Brocco G, Bassi A, Salvagno GL. Estimating the intra- and inter-individual imprecision of manual pipetting. Clinical Chemistry and Laboratory Medicine (CCLM). 2017;55(7). doi:10.1515/cclm-2016-0810

- Sertkaya A, Beleche T, Jessup A, Sommers BD. Costs of Drug Development and Research and Development Intensity in the US, 2000-2018. JAMA Netw Open. 2024;7(6):e2415445. doi:10.1001/jamanetworkopen.2024.15445