Multiplexed POC Test on Unmodified Surfaces

Early and accurate diagnosis of specific diseases

Introduction

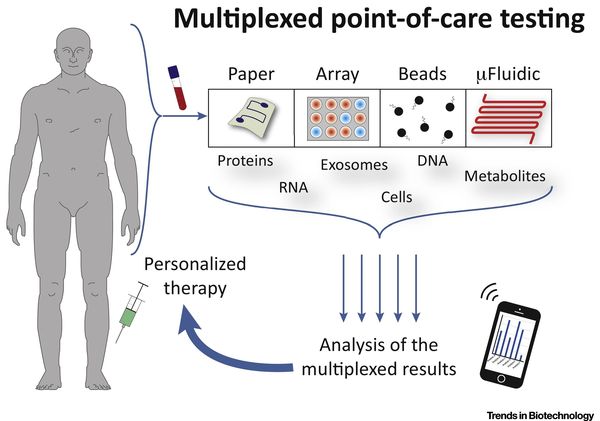

An early and accurate diagnosis of a specific disease plays a decisive role for its effective treatment. Especially at the point of care, where an immediate decision on treatment most needs to be made, such as in cases of stroke or sepsis, the rapid and precise confirmation of clinical findings is vital.

However, in many instances (e.g., to distinguish between the different types of sepsis), clinical evidence based on a single biomarker is not adequate for an appropriate diagnosis of a disease or for monitoring its treatment.

In addition, it is highly desirable to screen various analytes simultaneously, enabling a rapid, low-cost, and reliable quantification. Therefore, multiplexing has become more important for point-of-care testing in the last decade. In this context, there is a great demand for xPOCT devices, which ensure the quality and performance requirements of in vitro diagnostics, performed in a short period by non-experts. This will also pave the way for novel home health monitoring systems and add valuable information for personalized medicine.

POC Periodontitis Testing

Based on a patented combination of microfluidics, miniaturized opto-electronics and automation, GENSPEED®, an Austrian biotech company, has developed a compact, simple and reliable test for identification of key pathogens associated with periodontitis.

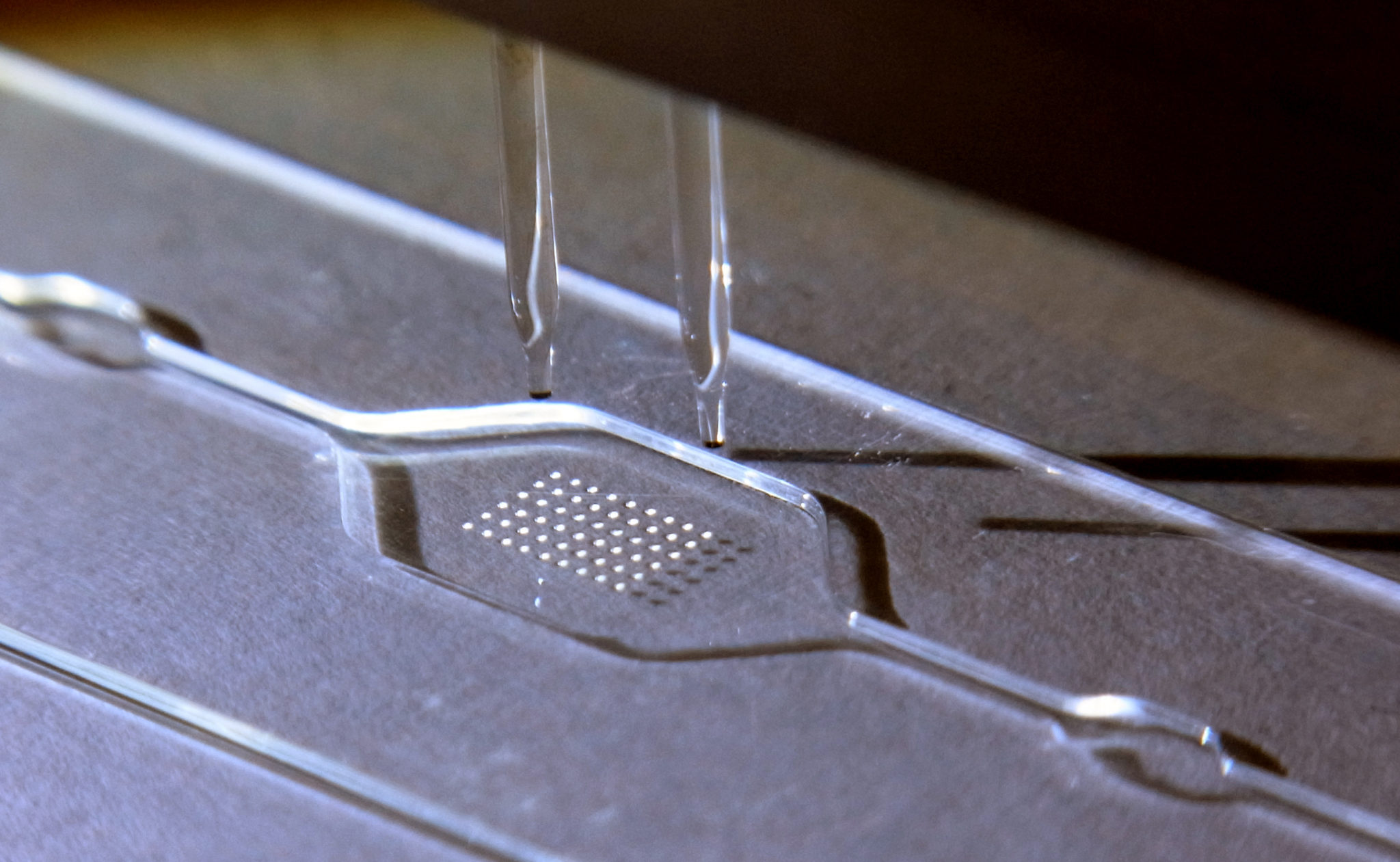

Based on an array printed with sciFLEXARRAYER technology in a polymer chip, GENSPEED´s “Multiplexed Micro-ELISA” system allows the detection of up to 8 different biomarkers in a single run at the point of care within only a few minutes and with high sensitivity.

Key features of the test include multiplex assays (≤ 8 parameters), quantitative results, automated rapid testing (results in ~ 15 minutes), easily adaptable to specific OEM customer requirements, lab-quality diagnostic results, IVD-CE certified hardware and software.

Related application note

Automated Multiplexed Quantification at the Point of Care

“It is great to work with SCIENION and to see how the company is bringing microarray printing to the next level. In particular, the new sciPOLY3D bears the potential to revolutionize microarray printing because it allows to print capture molecules on many surfaces without prior and costly surface modification procedures necessary.”

Dr. Max Sonnleitner, CEO of GENSPEED Biotech GmbH

Since the beginning of their development, GENSPEED has trusted SCIENION technology for the production of all their IVD tests.

One of the challenges of the printing of their chip was to ensure that the capture molecules would remain on the polymer surface. The strategy that SCIENION suggested in order to avoid prior and costly surface modification was to add sciPOLY 3D, our innovative solution to print on unmodified surfaces.

Results have proven excellent when printing on non modified PS; capture molecules were directly printed on the PS foil without the need of any prior modification.

DNA & Protein microarrays on unmodified surfaces

One major task for the design of microarray based nucleic acid tests is the decision for a platform and substrate material, e.g. polymer microfluidic cartridges, microwell plates, slides or membranes.

This choice usually is constrained by the immobilization chemistry. Most conventional immobilization strategies for proteins rely on adsorptive immobilization only or surface functionalization of the whole substrate with e.g. carboxy or epoxy moieties.

sciPOLY3D: the solution for printing microarrays on unmodified surfaces

SCIENION has developed an innovative solution to print microarrays on unmodified surfaces. sciPOLY3D enables the immobilization of DNA and proteins in all common plastic substrates, such as COP, PMMA, COC, PP, etc. and even non-fouling surfaces can be used for microarray applications.

The use of sciPOLY3D eliminates all wet chemistry steps in the microarray manufacturing process. This facilitates especially the protein immobilization on structured substrates, such as microfluidic chips and on substrates that are not suitable for adsorptive immobilization.

With sciPOLY3D, proteins can be covalently attached to virtually all polymers without pre-treatment thereof and even on protein-repellent surfaces.

sciPOLY3D is water soluble and is simply added to the printing media. The only additional process step is a short illumination with UV light after printing.

Thus, the whole process of microarray production is reduced to printing and an additional few minutes for irradiation, which can easily be integrated into a high-throughput microarray production line.

Microfluidic CHIP from microLIQUID

“Here at Ophidia, we are working with a microfluidic chip made of polymer surface like COP, so we had to find a solution for efficient surface functionalization of our capture antibodies, therefore we are using sciPOLY 3D.”

Dr. Mirko Schlawinsky, Senior Biologist at Ophidia