sciDROP PICO

High precision microdispensing from picoliters to nanoliters

10 pL to 800 pL per drop

The technology, as patented by SCIENION, is called sciDROP PICO, and covers dispensing a liquid sample from 10 pL* to 800 pL per drop.

In combination with sciDROP NANO, the total volume range between 10 pL and 100 μL is covered by a single sciFLEXARRAYER instrument.

*results obtained with optimized samples and configuration.

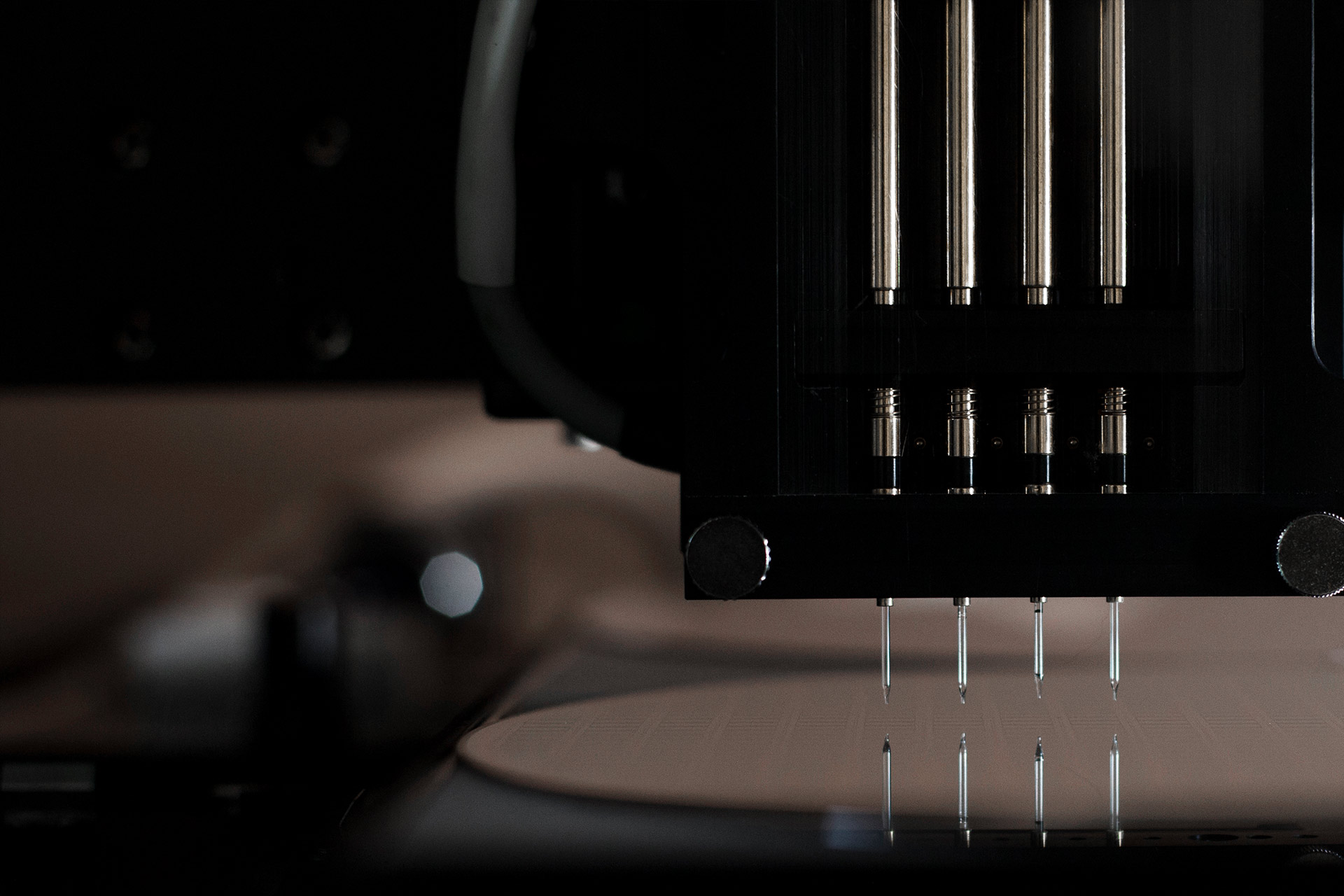

Non-contact technology offers a number of benefits over contact spotting

- Homogenous spot morphology

- No damage to sensitive surfaces, as can result from contacting metal pins

- Dispensing into very small cavities

- Drop volume is fully controlled by implementing a proprietary vision-based algorithm

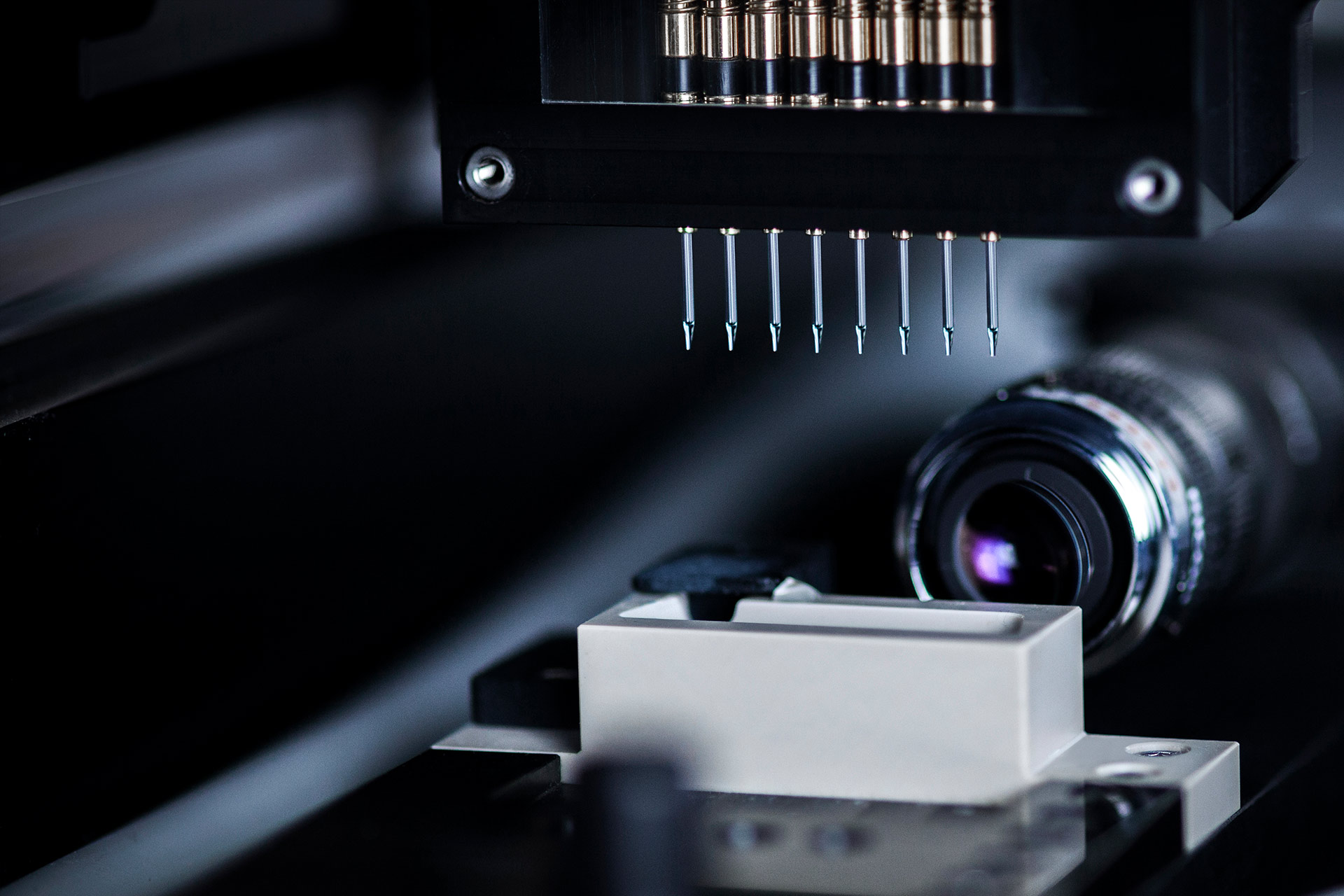

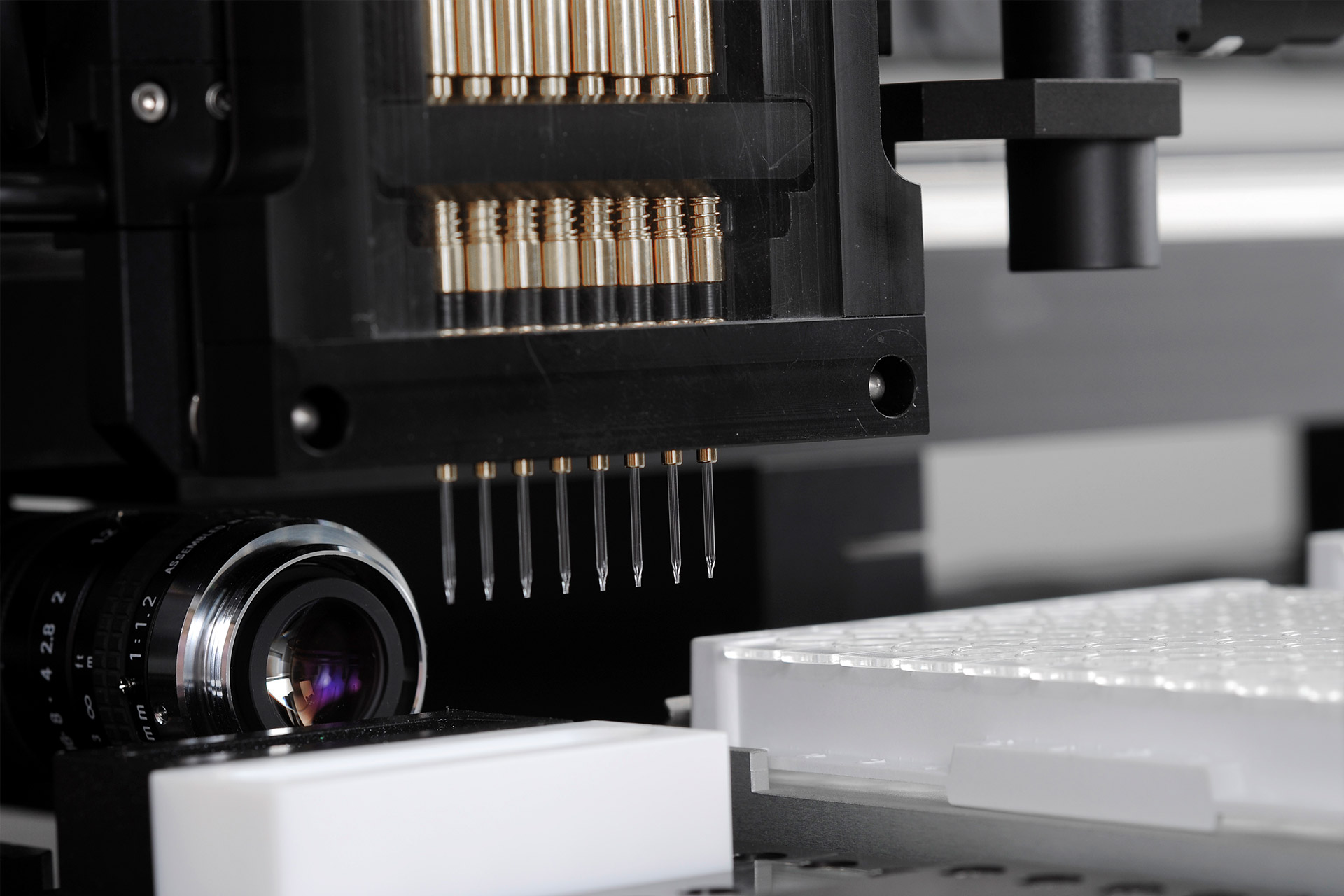

Piezo Dispense Capillaries

SCIENION’s sciDROP PICO is a state of the art non-contact dispensing technology based on piezo driven pulses on an inert glass capillary.

This enables accurate and precise droplet deposition under various conditions.

All Piezo Dispense Capillaries (PDCs) aspirate and dispense liquid at the picoliter scale. We will determine the best PDC size and coating combination for your specific application.

Benefits of sciDROP PICO

- Gentle acoustic dispensing of samples, no shear stress

- Living cells are successfully dispensed

- No added glycerol is needed in the system liquid

- Precise drop volume control with unique visual detection

- Absolute zero dead volume

- No crystallization of sample inside the tip due to a round orifice

- No satellite drops due to full drop ejection parameters control

Wide Range of Liquids

The sciDROP PICO option, together with SCIENION´s surface coating technology, provides access to a broad field of applications with high accuracy and precision dispensing a wide range of liquids:

Biomolecules using water based printing buffers

Small molecules using a range of organic solvents

A large number of other various viscous liquids

Dispensable Media

Thanks to our surface characterization expertise, we have developed inert glass Piezo Dispense Capillaries (PDCs) which can be coated to improve the quality of the dispensed solution. We have worked very successfully with the following solutions but this list is not exhaustive.

| Piezo dispensing | Non-contact |

| Capillary orifice | 35 – 75 µm |

| Spot frequency | 200 – 1500 Hz |

| Typical spot size | 80 – 250 µm |

| Average CV of drop volumes | <2%, typically < 0.5 % |

| Typical pitch (spacing) | Freely scalable (> 50 µm) |

| Capillary materials | Borosilicate glass, TEFLON® tube, PEEK fitting |

| Materials (in contact with medium) | PEEK, stainless steel, corundum |

| Viscosity of spotable media | 0.4 – 5 (mPa.s) |

| PDC 60 | 220-300 pl |

| PDC 70 | 300-360 pl |

| PDC 80 | 360-440 pl |

| PDC 90 | 440-520 pl |

| PDC 100 | 520-600 pl |

| PDC 110 | 600-800 pl |

| With coating types | |

| Type 1 | Aqueous solutions and organic solvents |

| Type 2 | Samples containing organic solvents like DMSO, DMF etc. and protein mixtures (lysates, allergens etc.) |

| Type 3 | Samples containing protein solutions and organic solvents like methanol, isopropanol, acetonitrile etc.) |

| Type 4 | Protein solutions and Sol-Gel samples |

| Coating special | According to customer specifications |