Search results: 2025

Your search "2025" yielded 9 results. You are on page 1 out of 1.

Evolution-proof: good reasons for being small.

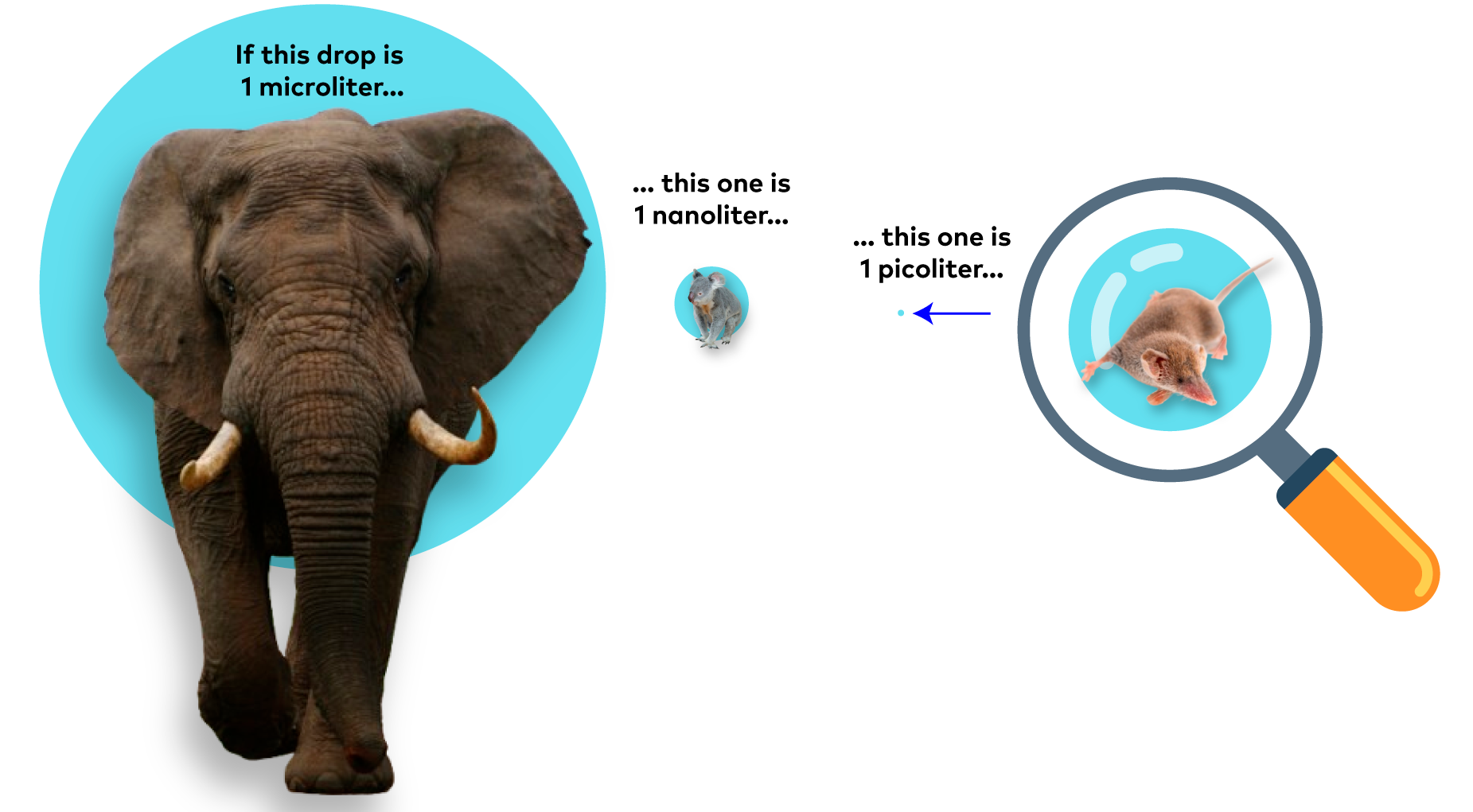

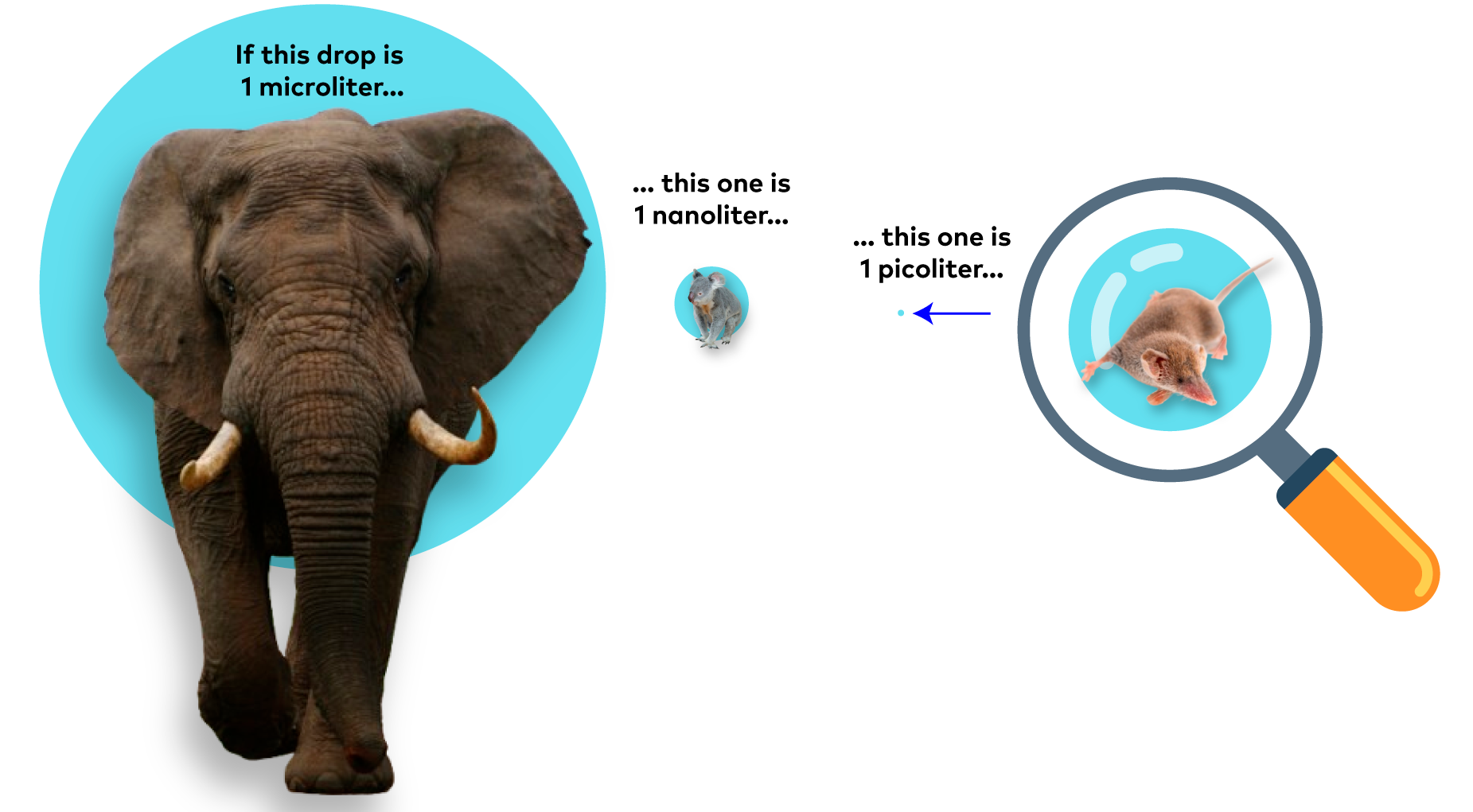

Sure, microliters, nanoliters and picoliters all sound small. But just like an elephant, a koala, and a Etruscan shrew (the smallest mammal in the world), evolution has shown that even small ones can be giants, too!

Precision microdispensing deals in these tiny volumes, where even a small difference can have a big impact. Where every drop counts, knowing the scale matters!

Accelerate your science.

Being small offers you several advantages: you are often faster, more flexible and need less to get your daily life done. Good luck if you need to catch a mouse by hand in your basement next time.

Like in nature, precision microdispensing has all the advantages of miniaturization: more speed by multiplexing, higher accuracy and flexibility in combination with less waste and efforts. Means: a whole lot of science done right!

Tiny Spots, Huge Impact!

Imagine fitting hundreds—even thousands—of different tests onto a surface no bigger than a postage stamp. That’s the magic of microarrays: each minuscule spot holds a unique reagent, like antibodies or PCR primers, allowing for massive parallel testing in a compact space.

The key to this technology? Picoliter liquid dispensing. Accurate positioning and volume of each spot ensure reliable results and cost-effective diagnostics. Think of it as pixel-perfect printing for the molecular world—where every dot matters.

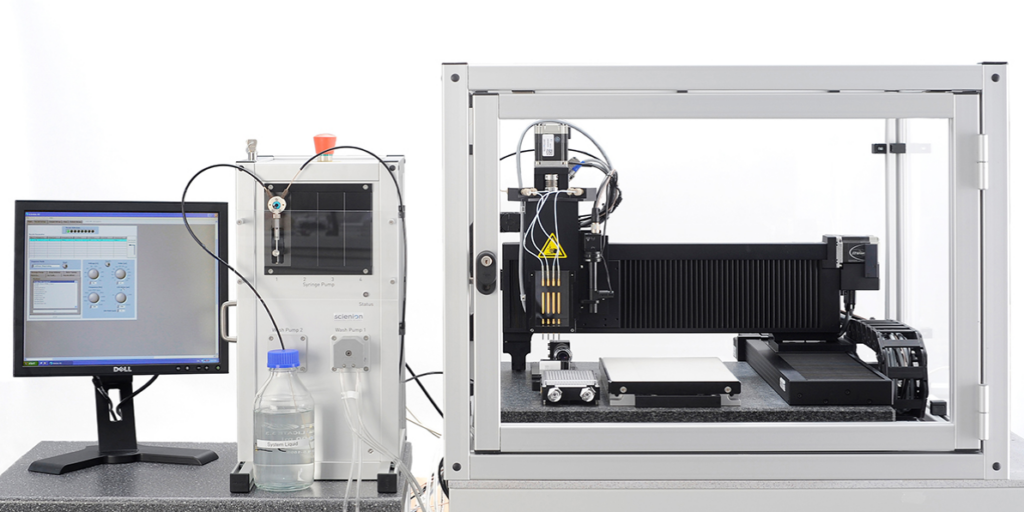

When Precision Meets Innovation: The sciFLEXARRAYER Advantage

In the world of picoliter dispensing, the sciFLEXARRAYER stands out as the maestro of micro-drops. Equipped with SCIENION’s patented sciDROP PICO technology, it delivers drop-on-demand dispensing from 10 pL to 800 pL per drop. This non-contact, piezo-driven system ensures each droplet lands exactly where it’s needed, every single time.

Whether you’re crafting intricate microarrays or loading biosensors, the sciFLEXARRAYER offers unparalleled accuracy and flexibility. From R&D to high-throughput manufacturing, it’s the go-to instrument for scientists who refuse to compromise on precision.

With the sciFLEXARRAYER, you’re not just dispensing liquids; you’re placing confidence in every picoliter!

Enzyme-linked Immunosorbent Assays (ELISAs) have long been the benchmark for detecting analytes in clinical and research settings. While effective, traditional ELISAs are resource-intensive, time-consuming to perform, and ill-suited for high-throughput, multiplex applications. As scientific workflows demand faster and more cost-efficient solutions, it is clear that the classic format needs a modern upgrade. Miniaturized ELISAs offer a powerful upgrade, leveraging picoliter dispensing to cut costs, accelerate timelines, and scale assays without sacrificing data quality. In this article, we discuss the shortcomings of traditional ELISA and how miniaturization paves the way for faster, scalable, and more efficient assays across diverse applications.

Why ELISA Needs an Upgrade

ELISA is the gold standard for immunodetection of target analytes and has been an enduringly valuable tool for both research and clinical applications. ELISA has proven particularly revolutionary in assessing infection status and remains a cornerstone of both routine diagnostics and cutting-edge research across various biomedical fields [1,2]. For example, healthcare professionals use it to measure levels of circulating antibodies against various pathogens, such as Hepatitis viruses and HIV, as well as for health screening purposes, like assessing prostate-specific antigen levels [3,4].

Despite its importance and ubiquity, this technique has limitations that render it a less viable option in modern workflows. It can be:

- Resource-intensive: They typically involve multiple steps (e.g., coating, blocking, washing, incubation), which take several hours and require qualified personnel for performance and interpretation.

- Reagent-intensive: They involve the use of expensive primary antibodies and potentially large volumes of different buffers and washing reagents when performed at large scales.

- Prone to variability: Lot-to-lot variation in antibodies or substrates can lead to inconsistent results over time. Cross-reactivity or non-specific binding can result in incorrect results. Improper washing or reagent issues can also affect accuracy. Furthermore, manual pipetting of ELISAs introduces additional challenges, such as increased risk of human error, underscoring the need for modern alternatives [5].

- Hard to mutiplex: Even at 96- and 384-well formats, multiplexing challenges can put a spanner in the works for teams looking to achieve resource efficiency while meeting competitive timelines.

The Case for Miniaturized ELISA

One solution that can address the problems of cost, throughput, and multiplexing is ELISA miniaturization. Thanks to technological advances, many assays and laboratory processes can now be scaled down, volume-wise, reducing the amount of reagents and sample required. A miniaturized ELISA can be performed using microarray or chip formats and scaled down to reaction volumes in the micro-, nano-, and picoliter ranges using a dedicated microdispenser. These capabilities bring several advantages to researchers, including:

- Conserving reagents: Miniaturization reduces reagent volumes per reaction, and precision microdispensers are designed to have low dead-volume, wasting less liquid between runs. This lowers overall consumable use and costs, freeing up budget for achieving greater throughput or addressing other experimental needs.

- Higher throughput: Microdispensing systems can rapidly process multiple microwells or microarrays, increasing throughput, so that researchers can process more samples in parallel. This facilitates large-scale studies, where accuracy isn’t impacted by inter-run variations.

- Faster workflows: Processing more samples at once shortens both research and clinical timelines, enabling faster clinical decision-making and potentially improving patient outcomes. Moreover, automated dispensers, and their possible integration with other robotic systems, reduce hands-on time, error, and variability across large sample sets [6].

- Multiplexing: Miniaturized ELISA platforms, including those that utilize picoliter dispensing, enable the simultaneous detection of multiple analytes within a single assay. This conserves sample, increases data density, and allows more comprehensive analysis in a single run.

- Better reproducibility: Precision microdispensers can deliver accurate, repeatable picoliter to microliter volumes of reagents, minimizing human error and variability. Uniform droplet deposition improves antigen/antibody binding consistency across wells or slides, leading to more reliable results.

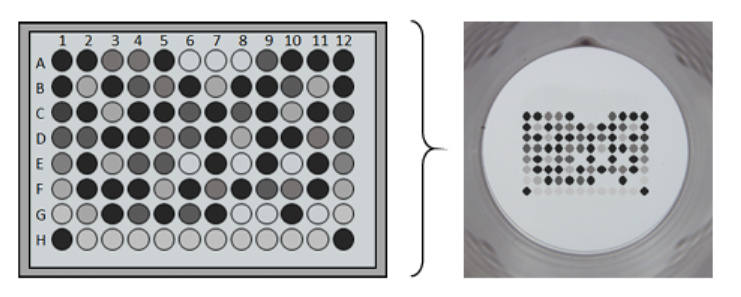

For example, SCIENION’s sciFLEXARRAYER line enables ELISAs that would normally consume an entire 96-well plate to be performed within a single well, resulting in a more than 100-fold reduction in material consumption (Fig. 1).

Figure 1. A sciFLEXARRAYER was used to produce a microarray ELISA with approximately 700 pL per spot, resulting in spots with a diameter of roughly 190 µm. Read the full application note to learn how this technology was used to assess cardiovascular disease biomarkers.

Precision Dispensing Challenges in Miniaturized Assays

Miniaturization relies on precision dispensing and is increasingly being adopted in clinical and research workflows. However, not all miniaturization technologies are created equal. While addressing the challenges of traditional ELISA, they also introduce new issues that can delay timelines or compromise data quality.

Inconsistent droplet volumes can cause variability across ELISA workflows. Adding too little or too much of a primary antibody affects antigen binding, resulting in variation, and possibly false negative/positive results. This inconsistency makes it difficult for researchers to draw reliable conclusions or reproduce results. Additionally, poor spot alignment and irregular spot morphology can create similar issues. Some dispensing technologies also rely on contact-based methods, which carry a higher risk of cross-contamination and issues with spot morphology.

These limitations can leave researchers back where they started, forcing them to confront the same challenges as traditional, non-miniaturized manual methods, and wasting valuable resources and generating inconsistent, unreliable data.

SCIENION Technology for Effective ELISA Miniaturization

SCIENION’s sciFLEXARRAYER instruments help overcome many of the ELISA challenges by enabling highly accurate, non-contact dispensing of volumes as small as 10 picoliters. These platforms also offer the flexibility to adapt experimental approaches to varying scales and multiplexing requirements. This technology ensures consistent microdispensing, meaning volumes and spot morphologies are consistent within and across runs.

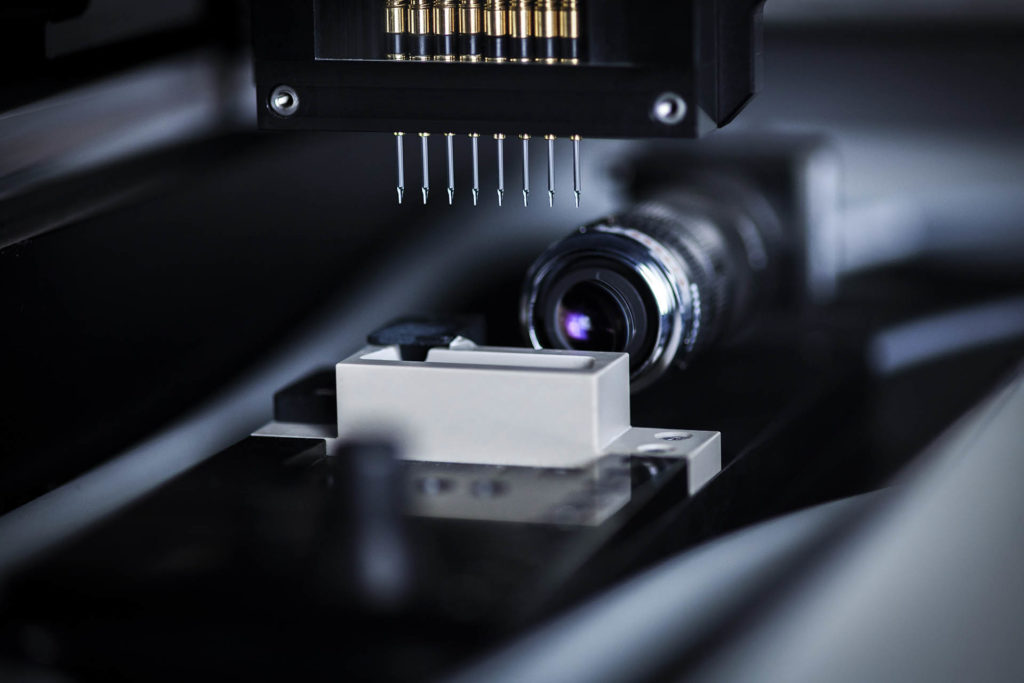

Furthermore, SCIENION technology achieves zero dead volume and utilizes non-contact dispensing, enabling researchers to preserve expensive reagents and prevent cross-contamination (Fig. 2). Moreover, sciFLEXARRAYER comes in a full range of instruments from models designed for research and methodological development (e.g., sciFLEXARRAYER S3) to fully integrated systems for high-throughput manufacturing (sciFLEXARRAYER S100). This scalability allows laboratories and production facilities alike to benefit from the precision and reliability of SCIENION’s dispensing technology.

Figure 2. SCIENION instruments utilize piezo-acoustic dispensing of ultra-low volumes, down to 10 pL, and achieve absolute zero dead volume and precision positioning for accurate and multiplexed ELISA.

Use Cases & Applications

Backed by a robust microdispenser, researchers can unlock entire vistas of potential applications while boosting the speed and efficiency of their existing ELISA workflows. Applications that benefit from ELISA miniaturization include:

- Multiplex Cytokine Profiling: Miniaturized ELISAs enable the simultaneous measurement of numerous cytokines from small sample volumes, allowing for comprehensive immune profiling and accelerating the identification of inflammatory markers to inform clinical decision-making and unlock new therapeutic approaches.

- Infectious Disease Panels: Miniaturized ELISAs can be used to detect antibodies for multiple pathogens in a single test, streamlining infectious disease diagnostics by conserving samples and significantly reducing turnaround time. Miniaturization can be especially valuable in complex cases with limited sample availability [7].

- Biomarker Discovery and Validation: By enabling assay multiplexing, miniaturization can achieve rapid screening of candidate biomarkers from clinical samples. Without a precision dispenser, applications like this would be prohibitively expensive and likely consume too much sample to be viable.

Conclusion

Miniaturized ELISA platforms are redefining what’s possible in diagnostics and research. With precise, non-contact dispensing platforms like SCIENION’s sciFLEXARRAYER, scientists can overcome traditional ELISA limitations while unlocking high-throughput, multiplexed, and sample-efficient workflows. These advancements reduce timelines and conserve precious reagents, enabling advancements in diagnosis and discovery applications. ELISA miniaturization helps alleviate the perennial pressure for higher efficiency without compromising sensitivity or data quality.

Talk with one of our experts to learn more about how SCIENION can help you scale multiplexed immunoassays.

References

- Ho A, Galgut O, Faustini S, Peters N, Shields A, Klenerman P, et al. Implications of suboptimal measles immunity in UK health-care workers. Lancet. 2024 Jul 6;404(10447):23–4.

- Aydin S. A short history, principles, and types of ELISA, and our laboratory experience with peptide/protein analyses using ELISA. Peptides. 2015 Oct;72:4–15.

- Rissin DM, Kan CW, Campbell TG, Howes SC, Fournier DR, Song L, et al. Single-molecule enzyme-linked immunosorbent assay detects serum proteins at subfemtomolar concentrations. Nat Biotechnol. 2010 Jun;28(6):595–9.

- Ly TD, Laperche S, Couroucé AM. Early detection of human immunodeficiency virus infection using third- and fourth-generation screening assays. Eur J Clin Microbiol Infect Dis. 2001 Feb;20(2):104–10.

- Lippi G, Lima-Oliveira G, Brocco G, Bassi A, Salvagno GL. Estimating the intra- and inter-individual imprecision of manual pipetting. Clinical Chemistry and Laboratory Medicine (CCLM) [Internet]. 2017 Jan 27 [cited 2024 Sep 2];55(7). Available from: https://www.degruyter.com/document/doi/10.1515/cclm-2016-0810/html

- Holland I, Davies JA. Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol. 2020;8(571777).

- Siavashy S, Soltani M, Rahimi S, Hosseinali M, Guilandokht Z, Raahemifar K. Recent advancements in microfluidic-based biosensors for detection of genes and proteins: Applications and techniques. Biosensors and Bioelectronics: X. 2024 Aug;19:100489.

Evolution-proof: good reasons for being small.

Sure, microliters, nanoliters and picoliters all sound small. But just like an elephant, a koala, and a Etruscan shrew (the smallest mammal in the world), evolution has shown that even small ones can be giants, too!

Precision microdispensing deals in these tiny volumes, where even a small difference can have a big impact. Where every drop counts, knowing the scale matters!

Accelerate your science.

Being small offers you several advantages: you are often faster, more flexible and need less to get your daily life done. Good luck if you need to catch a mouse by hand in your basement next time.

Like in nature, precision microdispensing has all the advantages of miniaturization: more speed by multiplexing, higher accuracy and flexibility in combination with less waste and efforts. Means: a whole lot of science done right!

Tiny Spots, Huge Impact!

Imagine fitting hundreds—even thousands—of different tests onto a surface no bigger than a postage stamp. That’s the magic of microarrays: each minuscule spot holds a unique reagent, like antibodies or PCR primers, allowing for massive parallel testing in a compact space.

The key to this technology? Picoliter liquid dispensing. Accurate positioning and volume of each spot ensure reliable results and cost-effective diagnostics. Think of it as pixel-perfect printing for the molecular world—where every dot matters.

When Precision Meets Innovation: The sciFLEXARRAYER Advantage

In the world of picoliter dispensing, the sciFLEXARRAYER stands out as the maestro of micro-drops. Equipped with SCIENION’s patented sciDROP PICO technology, it delivers drop-on-demand dispensing from 10 pL to 800 pL per drop. This non-contact, piezo-driven system ensures each droplet lands exactly where it’s needed, every single time.

Whether you’re crafting intricate microarrays or loading biosensors, the sciFLEXARRAYER offers unparalleled accuracy and flexibility. From R&D to high-throughput manufacturing, it’s the go-to instrument for scientists who refuse to compromise on precision.

With the sciFLEXARRAYER, you’re not just dispensing liquids; you’re placing confidence in every picoliter!

The need for rapid, reliable, and scalable diagnostic tests has never been greater, whether it’s for addressing challenges with SARS-CoV-2 infections or detecting sexually transmitted diseases like HIV and other pathogens. To meet these needs, manufacturers are turning to precision liquid microdispensing technology, which enables miniaturization of multiplex assays, exceptional accuracy, and scalable high-throughput production. This innovation is transforming diagnostic manufacturing by improving efficiency, reducing waste, and ensuring consistent test performance. In this article, we explore how precision microdispensing is shaping the future of diagnostics, making advanced healthcare solutions more accessible, cost-effective, and impactful worldwide.

How Precision Dispensing is Transforming Diagnostic Manufacturing

Meeting the Demand for Diagnostic Tools

The global demand for rapid, cost-effective diagnostic tests continues to grow, driven by the need for accessible, locally deployable, point-of-care tests [1]. The COVID-19 pandemic underscored the urgent need for advanced testing infrastructure and highlighted the importance of rapidly and reliably detecting pathogens [2]. Additionally, there remains a critical demand for diagnostic tools to assess food and water safety, such as microbes in drinking water [3,4].

To meet these challenges, diagnostic tools must offer the highest sensitivity on one hand and cost-efficiency on the other. However, their development requires cutting-edge manufacturing technologies that ensure accuracy, reliability, and scalability.

For example, to address the need for precancer screening in cervical cancer, researchers used the sciFLEXARRAYER S3 from SCIENION to develop a point-of-care test for cancer-associated proteins. Due to its low production costs, this test might enable low- and middle-income countries to improve and extend diagnostic testing procedures, as the high costs and usability challenges of the current healthcare system have previously been significant barriers [5].

As the demand for such tests increases, so does the need for advanced production techniques to create smaller, more efficient, and highly sensitive diagnostic solutions [6].

Precision Dispensing: Advanced Solutions for Today’s Challenges

The modern medical landscape increasingly relies on point-of-care testing solutions, particularly in the wake of the COVID-19 pandemic, where diagnosis in the domestic setting reduced the strain on healthcare infrastructure [7]. Advanced precision dispensing at micro-, nano-, and picoliter scales might open new possibilities for developing next-generation diagnostic tools. By leveraging automation and technologies like the Piezo dispense capillary (PDC) based sciDROP PICO, these capabilities enhance accuracy and quality.

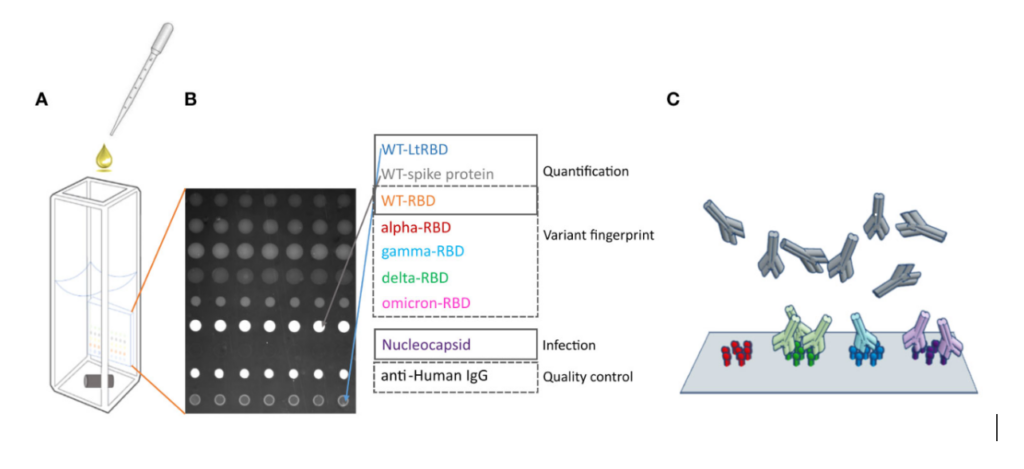

Recently, researchers used SCIENION technology to create a multiplex assay for SARS-CoV-2, allowing them to observe how individuals’ serum antibody profiles varied depending on their exposure to different viral variants and their vaccination status (Fig. 1) [8]. This involved the dispensing of viral antigens and control protein in 150–200-μm spots on reflective phantom interface (RPI) sensing chips.

Recent dispensing innovations ensure precise fluid handling, enabling the miniaturization of tests without compromising their performance, ultimately driving advancements in global healthcare diagnostics while reducing the amount of sample and expensive reagents required per test [6].

Figure 1. SCIENION’s technologies helped researchers develop an assay to detect serum antibodies targeting different SARS-CoV-2 antigens.

Adapted from:

https://www.frontiersin.org/journals/immunology/articles/10.3389/fimmu.2024.1323406/full

From R&D to Implementation – The Eurostars E*LOGIC Project

The Challenge:

Monitoring antibiotic residues in food is a critical requirement to ensure consumer safety and comply with stringent global regulations [9]. To address this challenge, the Eurostars project E*LOGIC was launched to develop a rapid, multiplex immunodiagnostic test capable of detecting seven key antibiotic targets across four major drug families (Nitrofurans, Tetracyclines, Nitroimidazoles, and Chloramphenicol) in the seafood and honey industries.

The Solution:

SCIENION played a pivotal role in developing this diagnostic tool by leveraging its cutting-edge sciFLEXARRAYER technology. The non-contact dispensing system enabled precise microarray printing of binding ligands on nitrocellulose membranes, ensuring high sensitivity and reliability. Carbon nanoparticles were integrated as detection labels, further enhancing accuracy. SCIENION also contributed to scaling up production by optimizing test parameters, including membrane pore size, reagent concentrations, and automated quality control.

The Impact:

The resulting prototype kit allows rapid detection within 10 minutes, significantly reducing testing time and costs for seafood and honey producers, government laboratories, and regulatory bodies.

Learn more about the E*LOGIC Project and other success stories.

Key Advantages of Precision Liquid Dispensing in Diagnostics

Microdispensing comes with several benefits for the production and development of diagnostic tools. Primary advantages include:

Ultra-Low Volume Dispensing

Ultra-low volume dispensing allows researchers to use only a minimal amount of reagents when developing and producing diagnostic tests. This approach reduces waste and optimizes resource efficiency. Additionally, when paired with a dispensing technology like the sciDROP PICO from SCIENION, researchers can achieve even greater efficiency thanks to its zero dead volume capability.

High-Throughput Automation

Automation offers a wide range of benefits, including faster processing and reduced errors commonly associated with manual handling and dispensing [10]. High-throughput automated microdispensing capabilities enable significantly faster processing, making it ideal for the rapid, large-scale production of diagnostic tests—an essential factor in responding to emerging healthcare emergencies, such as the COVID pandemic, where millions, if not billions, of lateral flow tests were required almost overnight.

Precision and Consistency

Advanced microdispensers enable precise liquid dispensing at volumes as low as 10 pL. They also enhance assay performance by executing consistent and programmable dispensing tasks without manual intervention. This ensures that assays can be developed with precision and uniformity across multiple geographic locations, delivering reliable and reproducible results that meet regulatory requirements and quality standards.

Flexibility

Flexibility is a key advantage throughout the transition from development to full-scale manufacturing. It gives researchers the flexibility to make adjustments early in the process without significant losses in time and resources, which would be more costly at later stages. Once manufacturing is optimized, processes can be quickly scaled up while still using minimal reagent quantities, ensuring cost efficiency even in large-scale production. sciFLEXARRAYER instruments from SCIENION provide dispensing solutions for all scales, from exploratory work and batch printing to high-throughput manufacturing. This flexibility sets SCIENION’s offerings apart from competitors.

How Scienion’s Technology Enables High-Performance Diagnostics

Picoliter Dispensing and Nanoliter Pipetting for Miniaturization and Accuracy

Picoliter dispensing enables the miniaturization of diagnostic production and development. Smaller droplet sizes, compared to other dispensing methods, allow for multiplexing of assays using smaller devices while increasing the density of analytical components within a single unit. This leads to reduced raw material consumption and improved throughput.

For precise and reproducible nanoliter dispensing, SCIENION’s sciDROP NANO technology offers a reliable solution. It delivers dispensing precision with a coefficient of variation of less than 2%, ensuring uniform assay reagent deposition for more accurate testing and successful product development.

SCIENION vs. the Competition

SCIENION provides researchers with highly flexible and efficient dispensing solutions across various applications. The sciFLEXARRAYER range offers precise control over sample deposition, supporting both full-line and segmented-line printing to optimize resource usage and minimize waste. The instruments support the customer at all phases, from development to mass production. For greater scalability, the sciDROP NANO and sciDROP PICO technologies seamlessly integrate with the sciFLEXARRAYER platform, enabling rapid printing and high-throughput production (Fig. 2).

Figure 2. sciFLEXARRAYER platform, an R&D entry platform, enables rapid and reproducible diagnostic assays.

With dispensing capabilities as low as 10 pL, SCIENION surpasses competitors, delivering greater precision and enhanced miniaturization. Additionally, SCIENION’s dispensing capillaries, handmade and QC’d in our Berlin facilities, can be coated with different solutions, enabling the dispensing of virtually any type of liquids, aqueous or organic, with minimal retention. SCIENION offers on-site support to help researchers fully leverage its dispensing technology, along with a comprehensive range of services, from Contract Development to Contract Manufacturing, enabling both researchers and diagnostics manufacturers to streamline their workflows and achieve cost and time savings.

The Future of Diagnostic Test Manufacturing

Precision liquid microdispensing is transforming diagnostic manufacturing, making it possible for companies to produce high-performance, scalable, and cost-effective tests with exceptional accuracy. SCIENION is at the forefront of this innovation, providing cutting-edge dispensing solutions that enhance efficiency, reduce waste, and ensure consistent test performance. As the demand for advanced diagnostics grows, manufacturers must embrace precision dispenser technology to stay competitive.

Partner with SCIENION to accelerate your diagnostic development and bring next-generation healthcare solutions to market faster than ever.

References

- Dinnes J, Sharma P, Berhane S, van Wyk SS, Nyaaba N, Domen J, et al. Rapid, point-of-care antigen tests for diagnosis of SARS-CoV-2 infection. Cochrane Database Syst Rev. 2022 Jul 22;7(7):CD013705.

- Harpaldas H, Arumugam S, Campillo Rodriguez C, Kumar BA, Shi V, Sia SK. Point-of-care diagnostics: recent developments in a pandemic age. Lab Chip. 2021 Nov 25;21(23):4517–48.

- CDC. Guidelines for Testing Well Water [Internet]. Drinking Water. 2024 [cited 2025 Mar 18]. Available from: https://www.cdc.gov/drinking-water/safety/guidelines-for-testing-well-water.html

- Arsenic [Internet]. [cited 2025 Mar 18]. Available from: https://www.who.int/news-room/fact-sheets/detail/arsenic

- Smith CA, Paul S, Haney KE, Parra SG, Bond M, López L, et al. A paper-based HPV E7 oncoprotein assay for cervical precancer detection at the point of care. Sci Rep. 2025 Jan 24;15(1):3041.

- Siavashy S, Soltani M, Rahimi S, Hosseinali M, Guilandokht Z, Raahemifar K. Recent advancements in microfluidic-based biosensors for detection of genes and proteins: Applications and techniques. Biosensors and Bioelectronics: X. 2024 Aug;19:100489.

- Khan AR, Hussain WL, Shum HC, Hassan SU. Point-of-care testing: a critical analysis of the market and future trends. Front Lab Chip Technol. 2024 May 13;3:1394752.

- Carzaniga T, Casiraghi L, Nava G, Zanchetta G, Inzani T, Chiari M, et al. Serum antibody fingerprinting of SARS-CoV-2 variants in infected and vaccinated subjects by label-free microarray biosensor. Front Immunol. 2024 Feb 27;15:1323406.

- Izah SC, Nurmakhanova A, Ogwu MC, Toktarbay Z, Umirbaeva Z, Ussen K, et al Public Health Risks Associated with Antibiotic Residues in Poultry Food Products. Journal of Agriculture and Food Research. 2025 Mar;101815.

- Holland I, Davies JA. Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol. 2020;8(571777).

How Picoliter Dispensing is Transforming Scientific Research and Innovation

In modern research, precision is everything. As scientists push the boundaries of innovation, picoliter dispensing has become an important tool, enabling ultra-miniaturized assays, reducing reagent waste, and enhancing experimental accuracy. Whether in biotech, diagnostics, or materials science, this technology brings speed without compromising quality and savings without reducing research output. From high-density biochips to biosensors, Microdispensing is enhancing workflows and empowering researchers to make groundbreaking discoveries. This article explores three key precision microdispensing applications, emphasizing the crucial role of automated picoliter-scale dispensing in advancing the next generation of scientific breakthroughs.

Why Picoliter Precision Matters in Modern Research

Modern research and development continually harnesses technological advancements to optimize resource allocation and streamline research objectives. One of the most notable examples of this progress is assay miniaturization, which allows researchers to obtain faster, more reliable results while reducing reagent consumption and minimizing hands-on time [1], [2]. Progress in this field has partly been driven by the development of picoliter precision dispensing technologies.

Accurate dispensing of increasingly low volumes empowers progress across biotech, diagnostics, and materials science applications. Picoliter dispensing simplifies and enhances highly sensitive molecular techniques in several key ways, including:

- Accuracy – Modern picoliter dispensers achieve accurate repeated dispensing of volumes as low as 10 pL. The droplet size is minuscule, roughly equivalent to three red blood cells arranged end-to-end.

- Density – The ability to dispense tiny droplets enables high-density sample arrays, maximizing data output while conserving reagents.

- Non-contact – Non-contact dispensing eliminates the risk of cross-contamination and ensures precise delivery.

- Automation – Automated processes enhance workflow efficiency by enabling high-throughput processing and reducing the potential for human error [3].

- Miniaturization – Precise dispensing minimizes reagent waste and maximizes the usability of rare or expensive samples.

Breakthrough Application #1: Biosensors

Many diagnostic workflows depend on the precise and sensitive detection of molecules within complex biological samples such as human-derived and environmental specimens. Biosensors are increasingly important in this space, providing rapid, reliable, and cost-effective solutions for detecting biomarkers and pathogens in real time, making them essential tools in modern diagnostics and beyond [4]. Environmental biosensors play a critical role in monitoring pollutants, detecting hazardous substances, and assessing ecosystem health, expanding the impact of biosensors beyond clinical applications [5].

Biosensors in Action

In a recent publication, researchers utilized CRISPR technology to detect pathogens in patient samples through Cas12a/gRNA-mediated cleavage of DNA probes labeled with methylene blue. Such a system can theoretically detect any nucleic acid sequence, offering exciting possibilities for robust and flexible diagnostic tests [6].

Microdispensing plays a crucial role in the fabrication of biosensors, ensuring precise reagent placement. By enabling accurate molecular detection while using minimal amounts of patient or environmental samples, picoliter dispensers enhance biosensor performance and reliability. Here’s why picoliter dispensing is an essential tool for advancing biosensor technology:

- Improved detection – Picoliter dispensing enables the precise placement of biomolecules in ultra-small volumes, increasing biosensor sensitivity to detect even trace amounts of target analytes in minimally diluted biological or environmental samples [7].

- Assay robustness – Ensures consistent and reproducible deposition of reagents, reducing variability between biosensors and improving assay reliability, which is crucial for clinical diagnostics and environmental monitoring [8].

- Automated production – Enables high-throughput and scalable biosensor manufacturing, minimizing human error and increasing efficiency, making it easier to produce reliable diagnostic tools for widespread use.

The highly versatile SCIENION’s sciDROP PICO microdispensing technology is compatible with a wide range of liquid types and is able to dispense any liquid volume from 10 pL to 100 µL, making it ideal for handling diverse sample types across broad biomedical applications.

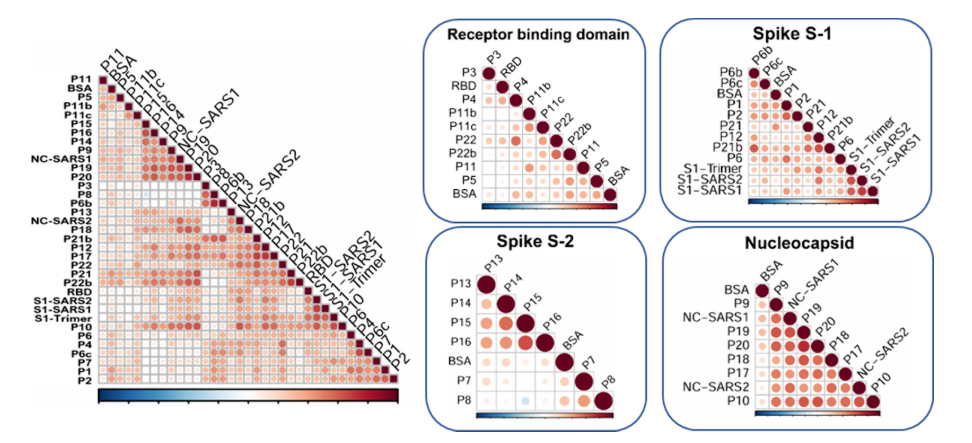

Breakthrough Application #2: Microarrays and High-Density Biochips

Microarrays and high-density biochips are laboratory tools that generate large volumes of genetic, proteomic, or biochemical information by detecting molecular interactions on a miniaturized, high-throughput platform. Microarrays are produced by dispensing arrays of dozens to thousands spots of reagents in nano- or pico-volumes, in precise patterns. Microarrays are widely understood to be used for genomic and transcriptomic analyses but can also be applied to proteome exploration. For example, using the sciFLEXARRAYER S3 from SCIENION, researchers created a multiplex array to evaluate individual responses to SARS-CoV-2 infection. This high-throughput, miniaturized platform enabled the detection of molecular interactions by analyzing patient sera binding to 28 different peptide epitopes and seven proteins on a 25 mm2 area of a glass slide (Fig. 1) [9].

Figure 1. Researchers used the sciFLEXARRAYER S3 to create a protein array to test for patient response to SARS-CoV-2 infections. Adapted from: https://pubs.acs.org/doi/full/10.1021/acsptsci.4c00727

These tools rely on highly sensitive liquid handling techniques, and their accuracy can be compromised if liquid dispensing is not precise and consistent during the fabrication of the array [10],[11]. Picoliter dispensing facilitates the miniaturization and automation of molecular array production workflows, resulting in faster and more reliable fabrication and improved accuracy over manual methods.

By adding multiple spots, each dedicated to the detection of a distinct biomolecule (such as the epitopes in Figure 1), picoliter dispensing enables the simultaneous analysis of multiple biomarkers, proteins, or genes within a single experiment, increasing throughput and efficiency while minimizing reagent use, as well as the volume of sample to be analysed.

Breakthrough Application #3: Drug Screening

Drug screening applications in biological and chemical research are challenging due to errors in manual dispensing and high reagent costs [12], [13]. Large-scale screening can be prohibitively expensive, while cell-based assays add variability and timing constraints, as cells respond differently depending on exposure duration.

Microdispensing addresses these challenges by enabling highly accurate, repeatable experiments at a tiny scale. Their precision minimizes waste, reduces costs, and ensures reliable results, making them invaluable for efficient and scalable screening applications.

- Reproducibility – Automated picoliter dispensing ensures consistent, error-free liquid handling, enhancing data reproducibility in drug screening [12].

- Cost-savings – Ultra-small volumes reduce reagent costs and waste, enabling more cost-effective large-scale drug screening.

- Versatility – Picoliter dispensing can be applied to various research areas, including chemical reaction monitoring, drug dose-response studies, biomarker discovery, and microarray printing (Fig. 2).

- Efficiency – Automated high-throughput dispensing accelerates screening, enabling rapid drug discovery and large-scale assays [1].

SCIENION sciDROP PICO precision dispenser technology enables precise dispensing of live cells with acoustic technology, preventing shear stress and providing reliability for cell-based screening, all while achieving zero dead volume.

Figure 2. sciDROP PICO technology achieves accurate dispensing from the nanoliter scale down to 10 pL of liquids of varying viscosities, including organic solvents. This gives researchers the flexibility to tackle complex workflows at any scale. sciFLEXARRAYER microdispensers may be equipped with up to 8 dispensing capillaries, dramatically increasing picoliter dispensing throughput.

How Picoliter Dispensing is Shaping the Future of Research

Microdispensing technology revolutionizes research by offering precision, minimizing reagent waste, and improving reproducibility. Across several precision microdispensing applications, from microarrays to biosensors and drug screening, these advancements enable more efficient workflows without compromising data quality. Nanoliter pipetting is also important in this area and supports broad applications in combination with picoliter dispensing. As automation and precision liquid dispensing become increasingly essential in modern research, adopting cutting-edge microdispensing solutions like SCIENION’s technology will ensure superior results and future-proof workflows.

Explore SCIENION’s microdispensing solutions today and unlock the full potential of miniaturized, high-precision experiments.

References

- Silva TC, Eppink M, Ottens M. Automation and miniaturization: enabling tools for fast, high‐throughput process development in integrated continuous biomanufacturing. J of Chemical Tech & Biotech. 2022;97(9):2365-2375. doi:10.1002/jctb.6792

- Cole RH, Tang SY, Siltanen CA, et al. Printed droplet microfluidics for on demand dispensing of picoliter droplets and cells. Proc Natl Acad Sci USA. 2017;114(33):8728-8733. doi:10.1073/pnas.1704020114

- Holland I, Davies JA. Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol. 2020;8(571777). doi:10.3389/fbioe.2020.571777

- Liu Z, Zhou Y, Lu J, et al. Microfluidic biosensors for biomarker detection in body fluids: a key approach for early cancer diagnosis. Biomark Res. 2024;12(1):153. doi:10.1186/s40364-024-00697-4

- Li Y, Chen B, Yang S, et al. Advances in environmental pollutant detection techniques: Enhancing public health monitoring and risk assessment. Environment International. 2025;197:109365. doi:10.1016/j.envint.2025.109365

- Carota AG, Bonini A, Urban M, et al. Low-cost inkjet-printed nanostructured biosensor based on CRISPR/Cas12a system for pathogen detection. Biosensors and Bioelectronics. 2024;258:116340. doi:10.1016/j.bios.2024.116340

- Siavashy S, Soltani M, Rahimi S, Hosseinali M, Guilandokht Z, Raahemifar K. Recent advancements in microfluidic-based biosensors for detection of genes and proteins: Applications and techniques. Biosensors and Bioelectronics: X. 2024;19:100489. doi:10.1016/j.biosx.2024.100489

- Beach ER, Benkstein KD, Montgomery CB, Semancik S, Morris PA. Picoliter drop deposition of SnO2 nanoparticles onto microsensor platforms. Sensors and Actuators B: Chemical. 2024;403:135152. doi:10.1016/j.snb.2023.135152

- Guercetti J, Alorda M, Sappia L, et al. Immuno- μSARS2 Chip: A Peptide-Based Microarray to Assess COVID-19 Prognosis Based on Immunological Fingerprints. ACS Pharmacol Transl Sci. 2025;8(3):871-884. doi:10.1021/acsptsci.4c00727

- Wong EY, Diamond SL. Advancing microarray assembly with acoustic dispensing technology. Anal Chem. 2009;81(1):509-514. doi:10.1021/ac801959a

- Shukla V, Hussin F, Hamid N, Zain Ali N. Advances in Testing Techniques for Digital Microfluidic Biochips. Sensors. 2017;17(8):1719. doi:10.3390/s17081719

- Lippi G, Lima-Oliveira G, Brocco G, Bassi A, Salvagno GL. Estimating the intra- and inter-individual imprecision of manual pipetting. Clinical Chemistry and Laboratory Medicine (CCLM). 2017;55(7). doi:10.1515/cclm-2016-0810

- Sertkaya A, Beleche T, Jessup A, Sommers BD. Costs of Drug Development and Research and Development Intensity in the US, 2000-2018. JAMA Netw Open. 2024;7(6):e2415445. doi:10.1001/jamanetworkopen.2024.15445